HEAT TREATED AND HOT FINISHED PIPES

ERW pipe can be quenched and tempered (Q&T) for additional toughness and rigidity at one of our three heat treatment facilities before being finished and prepared for shipment. The facility also features three threading facilities with capabilities ranging from 4-1/2” to 16” in all API thread configurations, as well as several specialty/premium thread connections.

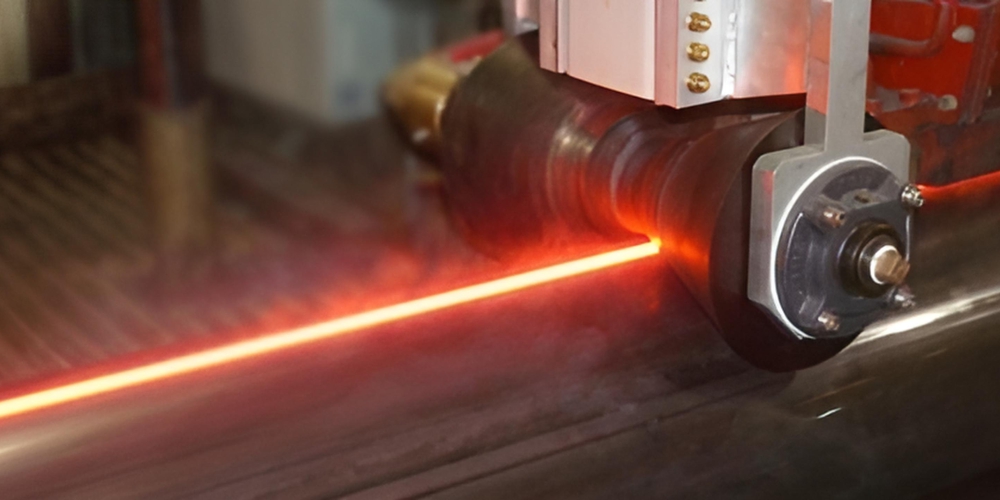

Steel arrives at the mill as coils slit to precise widths. The strip steel is uncoiled and levelled, then passed through a series of forming rolls, which transform the strip from flat steel to round pipe sections. The edges of the strip are contoured for seam welding and are then joined through the use of an electric current and applied pressure that welds the pipe edges together without the use of extra metal.

Once the weld is complete, the flash metal, which is extruded by the weld process, is removed from the ERW pipe inside and outside surfaces. The pipe is then cut to length by a flying rotary cut-off and weld’s integrity is checked by in-line ultrasonic test equipment.

Heat Treatment Types:

Stress Relieving

Normalization

Heat Treatment Areas:

Welding Seam + Heat Affected Zone (HAZ)

Full Body

Uniform grain structure through the full body normalizing operation:

Once tested, all ERW pipe passes through a battery of induction heating furnaces where it is heated to temperatures above 900 °C. It’s then sized through the Hot Stretch Reduction Mill (SRM), cut to ordered length and then air cooled. After cooling, every pipe is straightened, visually inspected, stencilled with the appropriate identify and queued for final finishing or quench and tempering. Laboratory tests confirm compliance to specifications and all other mechanical property requirements on all products that are not quenched and tempered before bevelling. In the case of products that are not quenched and tempered, laboratory tests confirm full compliance to specifications and other mechanical property requirements before any bevelling, eddy current inspection and hydrostatic testing. Full-body electromagnetic and ultrasonic testing is available for pipe sizes 4” and larger. Multiple certifications are available.

Advantages of Full Body Normalizing:

All welded tubes pass through a continuous normalizing furnace where they are heated above the steel pipe’s upper critical temperature, 900° to 1,040°C.

Hot working after full body normalizing initiates a very fine grain and homogenous microstructure. Residual stresses, untampered martensite and bainitic grain structure are eliminated in this process.

The result is a uniform microstructure that equates to consistent through wall hardness, yield and tensile properties both longitudinally and circumferentially along the length of each pipe.

High-Frequency Welded Seam Annealed products provide great performance in a variety of applications. However, variations in hardness and microstructure of the heat affected zone and pipe body can occur, which can have a negative impact on resistance to various types of corrosion. These variations are reduced with the grain refinement achieved during hot working at the normalizing temperatures of Full Body Normalized products.

This ERW process offers improved performance properties and product characteristics gained with Full Body Normalized product. Some of the advantages include:

- Full body normalizing and hot working provide a uniform microstructure that leads to consistent pipe - diameter, wall hardness, yield, and tensile properties.

- All quench and tempered pipes (Q&T) undergo a full body ultrasonic inspection.

- All pipe, regardless of grade, undergoes an ultrasonic weld line inspection after hydrotesting.

Supply Programme

Drilling Pipes:

Outside Dia. 26,67–114,3mm (1,050"–4 1/2")

Wall Thickness 2,87–9,65mm

Length 4,5–14,0 m

Casing Pipes:

Outside Dia. 114,3–339,72mm (4 1/2"-13 3/8")

Wall Thickness 5,21–13,06mm

Length 5,0–14,0m

Drill Rod Pipes:

Outside Dia. 69,9-88,9–114,3mm

Inner Dia. 60,3–77,8–101,6mm

Length 3,05m

Standards:

EN 10210 (CE), Grades S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H, S275NH, S275NLH, S355NH, S355NLH, S420NH, S420NLH.

Processes:

¬ Heat treatment

¬ Threading

¬ Galvanizing

¬ Primer Coating

¬ Polyethylene coating

¬ Internal Epoxy Coating

Supply Range for Full Body Heat-treated and Hot-finished Pipes:

| Outside Diameter | Wall Thickness (mm) | |||||||||||

| mm | inch | 1,5 | 2,0 | 2,5 | 2,6 | 2,9 | 3,0 | 3,2 | 3,5 | 3,6 | 4,0 | 4,5 |

| Unit Weight (kg/m) | ||||||||||||

| Ø21,3 | 1/2 | 0,73 | 0,95 | 1,16 | 1,20 | 1,32 | 1,35 | 1,43 | - | - | - | - |

| Ø22,0 |

| 0,76 | 0,99 | - | - | - | - | - | - | - | - | - |

| Ø25,0 |

| 0,87 | 1,13 | 1,39 | 1,44 | 1,58 | 1,63 | - | - | - | - | - |

| Ø26,7 | 3/4 | 0,93 | 1,22 | 1,49 | 1,55 | 1,70 | 1,75 | 1,85 | 2,00 | 2,05 | 2,24 | - |

| Ø26,9 | 3/4 | 0,94 | 1,23 | 1,50 | 1,56 | 1,72 | 1,77 | 1,87 | 2,02 | 2,07 | 2,26 | - |

| Ø28,6 |

| 1,00 | 1,31 | - | - | - | - | - | - | - | - | - |

| Ø32,0 |

| 1,13 | 1,48 | 1,82 | 1,89 | 2,08 | 2,15 | - | - | - | - | - |

| Ø33,4 | 1 | 1,18 | 1,55 | 1,90 | 1,97 | 2,18 | 2,25 | 2,38 | 2,58 | 2,65 | 2,90 | 3,21 |

| Ø33,7 | 1 | 1,19 | 1,56 | 1,92 | 1,99 | 2,20 | 2,27 | 2,41 | 2,61 | 2,67 | 2,93 | 3,24 |

| Ø35,0 |

| 1,24 | 1,63 | - | - | - | - | - | - | - | - | - |

| Ø38,0 |

| 1,35 | 1,78 | 2,19 | 2,27 | 2,51 | 2,59 | 2,75 | 2,98 | 3,05 | 3,35 | 3,72 |

| Ø40,0 |

| 1,42 | 1,87 | 2,31 | 2,40 | 2,65 | 2,74 | - | - | - | - | - |

| Ø42,2 | 1 1/4 | 1,51 | 1,98 | 2,45 | 2,54 | 2,81 | 2,90 | 3,08 | 3,34 | 3,43 | 3,77 | 4,18 |

| Ø42,4 | 1 1/4 | 1,51 | 1,99 | 2,46 | 2,55 | 2,82 | 2,91 | 3,09 | 3,36 | 3,44 | 3,79 | 4,21 |

| Ø45,0 |

| 1,61 | 2,12 | - | - | - | - | - | - | - | - | - |

| Ø48,3 | 1 1/2 | 1,73 | 2,28 | 2,82 | 2,93 | 3,25 | 3,35 | 3,56 | 3,87 | 3,97 | 4,37 | 4,86 |

| Ø50,0 |

| 1,79 | 2,37 | 2,93 | 3,04 | 3,37 | 3,48 | - | - | - | - | - |

| Ø51,0 |

| 1,83 | 2,42 | 2,99 | 3,10 | 3,44 | 3,55 | - | - | - | - | - |

| Ø57,0 |

| 2,05 | 2,71 | 3,36 | 3,49 | 3,87 | 3,99 | 4,25 | 4,62 | 4,74 | 5,23 | 5,83 |

| Ø60,3 | 2 | 2,18 | 2,88 | 3,56 | 3,70 | 4,10 | 4,24 | 4,51 | 4,90 | 5,03 | 5,55 | 6,19 |

| Ø63,0 |

| 2,27 | 3,01 | 3,73 | 3,87 | 4,30 | 4,44 | 4,72 | 5,14 | 5,27 | 5,82 | 6,49 |

| Ø73,0 | 2 7/8 | 2,64 | 3,50 | 4,35 | 4,51 | 5,01 | 5,18 | 5,51 | 6,00 | 6,16 | 6,81 | 7,60 |

| Ø76,1 | 2 1/2 | 2,76 | 3,65 | 4,54 | 4,71 | 5,23 | 5,41 | 5,75 | 6,27 | 6,44 | 7,11 | 7,95 |

| Ø80,0 |

| - | 3,85 | 4,78 | 4,96 | 5,51 | 5,70 | 6,06 | 6,60 | 6,78 | 7,50 | 8,38 |

| Ø88,9 | 3 | 3,23 | 4,29 | 5,33 | 5,53 | 6,15 | 6,35 | 6,76 | 7,37 | 7,57 | 8,37 | 9,37 |

| Ø96,0 |

| - | 4,64 | 5,76 | 5,99 | 6,66 | 6,88 | 7,32 | 7,98 | 8,20 | 9,07 | 10,15 |

| Ø101,6 | 3 1/2 | - | - | - | - | 7,06 | 7,29 | 7,76 | 8,47 | 8,70 | 9,63 | 10,78 |

| Ø114,3 | 4 | - | - | - | - | 7,97 | 8,23 | 8,77 | 9,56 | 9,83 | 10,88 | 12,18 |

| Ø125,0 |

| - | 6,07 | 7,55 | 7,85 | 8,73 | 9,03 | 9,61 | 10,49 | 10,78 | 11,94 | 13,37 |

| Ø127,0 |

| - | - | - | - | 8,87 | 9,17 | 9,77 | 10,66 | 10,95 | 12,13 | 13,59 |

| Ø133,0 |

| - | - | 8,05 | 8,36 | 9,30 | 9,62 | 10,24 | 11,18 | 11,49 | 12,72 | 14,26 |

| Ø139,7 | 5 | - | - | - | - | 9,78 | 10,11 | 10,77 | 11,76 | 12,08 | 13,39 | 15,00 |

| Ø152,4 |

| - | - | - | - | 10,69 | 11,05 | 11,77 | 12,85 | 13,21 | 14,64 | 16,41 |

| Ø159,0 |

| - | - | - | - | 11,16 | 11,54 | 12,29 | 13,42 | 13,80 | 15,29 | 17,14 |

| Ø165,1 | 6 | - | - | - | - | 11,60 | 11,99 | 12,78 | 13,95 | 14,34 | 15,89 | 17,82 |

| Ø168,3 | 6 | - | - | - | - | 11,83 | 12,23 | 13,03 | 14,22 | 14,62 | 16,21 | 18,18 |

| Ø177,8 | 7 | - | - | - | - | 12,51 | 12,93 | 13,78 | 15,04 | 15,46 | 17,14 | 19,23 |

| Ø193,7 | 7 5/8 | - | - | - | - | - | - | - | 16,42 | 16,88 | 18,71 | 21,00 |

| Ø219,1 | 8 | - | - | - | - | - | - | - | 18,61 | 19,13 | 21,22 | 23,81 |

| Ø244,5 | 9 | - | - | - | - | - | - | - | - | - | 23,72 | 26,63 |

| Ø273,0 | 10 | - | - | - | - | - | - | - | - | - | 26,53 | 29,80 |

| Ø323,9 | 12 | - | - | - | - | - | - | - | - | - | - | - |

| Ø339,7 | 13 3/8 | - | - | - | - | - | - | - | - | - | - | - |

| Outside Diameter | Wall Thickness (mm) | |||||||||||

| mm | inch | 5,0 | 5,5 | 6,0 | 6,5 | 7,0 | 8,0 | 9,0 | 10,0 | 11,0 | 12,0 | 13,0 |

| Unit Weight (kg/m) | ||||||||||||

| Ø21,3 | 1/2 | - | - | - | - | - | - | - | - | - | - | - |

| Ø22,0 |

| - | - | - | - | - | - | - | - | - | - | - |

| Ø25,0 |

| - | - | - | - | - | - | - | - | - | - | - |

| Ø26,7 | 3/4 | - | - | - | - | - | - | - | - | - | - | - |

| Ø26,9 | 3/4 | - | - | - | - | - | - | - | - | - | - | - |

| Ø28,6 |

| - | - | - | - | - | - | - | - | - | - | - |

| Ø32,0 |

| - | - | - | - | - | - | - | - | - | - | - |

| Ø33,4 | 1 | 3,50 | - | - | - | - | - | - | - | - | - | - |

| Ø33,7 | 1 | 3,54 | - | - | - | - | - | - | - | - | - | - |

| Ø35,0 |

| - | - | - | - | - | - | - | - | - | - | - |

| Ø38,0 |

| 4,07 | - | - | - | - | - | - | - | - | - | - |

| Ø40,0 |

| - | - | - | - | - | - | - | - | - | - | - |

| Ø42,2 | 1 1/4 | 4,59 | 4,98 | 5,36 | 5,72 | - | - | - | - | - | - | - |

| Ø42,4 | 1 1/4 | 4,61 | 5,00 | 5,39 | 5,75 | - | - | - | - | - | - | - |

| Ø45,0 |

| - | - | - | - | - | - | - | - | - | - | - |

| Ø48,3 | 1 1/2 | 5,34 | 5,80 | 6,26 | 6,70 | 7,13 | - | - | - | - | - | - |

| Ø50,0 |

| - | - | - | - | - | - | - | - | - | - | - |

| Ø51,0 |

| - | - | - | - | - | - | - | - | - | - | - |

| Ø57,0 |

| 6,41 | 6,98 | 7,55 | 8,09 | 8,63 | - | - | - | - | - | - |

| Ø60,3 | 2 | 6,82 | 7,43 | 8,03 | 8,62 | 9,20 | - | - | - | - | - | - |

| Ø63,0 |

| 7,15 | 7,80 | 8,43 | 9,06 | 9,67 | - | - | - | - | - | - |

| Ø73,0 | 2 7/8 | 8,38 | 9,16 | 9,91 | 10,66 | 11,39 | 12,82 | - | - | - | - | - |

| Ø76,1 | 2 1/2 | 8,77 | 9,58 | 10,37 | 11,16 | 11,93 | 13,43 | - | - | - | - | - |

| Ø80,0 |

| 9,25 | 10,10 | 10,95 | 11,78 | 12,60 | 14,20 | - | - | - | - | - |

| Ø88,9 | 3 | 10,34 | 11,31 | 12,27 | 13,21 | 14,14 | 15,96 | - | - | - | - | - |

| Ø96,0 |

| 11,22 | 12,27 | 13,32 | 14,35 | 15,36 | 17,36 | - | - | - | - | - |

| Ø101,6 | 3 1/2 | 11,91 | 13,03 | 14,14 | 15,24 | 16,33 | 18,47 | 20,55 | - | - | - | - |

| Ø114,3 | 4 | 13,48 | 14,76 | 16,02 | 17,28 | 18,52 | 20,97 | 23,37 | 25,72 | - | - | - |

| Ø125,0 |

| 14,80 | 16,21 | 17,61 | - | - | - | - | - | - | - | - |

| Ø127,0 |

| 15,04 | 16,48 | 17,90 | 19,31 | 20,71 | 23,48 | 26,19 | 28,85 | - | - | - |

| Ø133,0 |

| 15,78 | 17,29 | 18,79 | - | - | - | - | - | - | - | - |

| Ø139,7 | 5 | 16,61 | 18,20 | 19,78 | 21,35 | 22,91 | 25,98 | 29,01 | 31,98 | - | - | - |

| Ø152,4 |

| 18,17 | 19,92 | 21,66 | 23,39 | 25,10 | 28,49 | 31,83 | 35,12 | - | - | - |

| Ø159,0 |

| 18,99 | 20,82 | 22,64 | 24,44 | 26,24 | 29,79 | 33,29 | 36,74 | - | - | - |

| Ø165,1 | 6 | 19,74 | 21,65 | 23,54 | 25,42 | 27,29 | 30,99 | 34,64 | 38,25 | - | - | - |

| Ø168,3 | 6 | 20,13 | 22,08 | 24,01 | 25,93 | 27,84 | 31,62 | 35,36 | 39,04 | 42,67 | 46,25 | 49,79 |

| Ø177,8 | 7 | 21,31 | 23,37 | 25,42 | 27,46 | 29,48 | 33,50 | 37,46 | 41,38 | 45,25 | 49,06 | 52,83 |

| Ø193,7 | 7 5/8 | 23,27 | 25,53 | 27,77 | 30,01 | 32,23 | 36,63 | 40,99 | 45,30 | 49,56 | 53,77 | 57,93 |

| Ø219,1 | 8 | 26,40 | 28,97 | 31,53 | 34,08 | 36,61 | 41,65 | 46,63 | 51,56 | 56,45 | 61,29 | 66,07 |

| Ø244,5 | 9 | 29,53 | 32,42 | 35,29 | 38,15 | 41,00 | 46,66 | 52,27 | 57,83 | 63,34 | 68,80 | 74,21 |

| Ø273,0 | 10 | 33,04 | 36,28 | 39,51 | 42,72 | 45,92 | 52,28 | 58,59 | 64,86 | 71,07 | 77,24 | 83,35 |

| Ø323,9 | 12 | 39,32 | 43,18 | 47,04 | 50,88 | 54,70 | 62,32 | 69,89 | 77,41 | 84,88 | 92,30 | 99,67 |

| Ø339,7 | 13 3/8 | 41,27 | 45,33 | 49,37 | 53,41 | 57,43 | 65,44 | 73,40 | 81,30 | 89,16 | 96,97 | 104,73 |

| Lengths: | ||||||||||||

|

| 5,0-7,5m | |||||||||||

|

| 5,0-8,5m | |||||||||||

|

| 5,0-13,0m | |||||||||||

|

| 5,0-14,0m | |||||||||||

Supply Range for Welding Seam and HAZ Heat Treated Pipes:

| Outside Diameter | Wall Thickness (mm) | |||||||||||

| mm | inch | 2,0 | 2,5 | 2,6 | 2,9 | 3,0 | 3,2 | 3,5 | 3,6 | 4,0 | 4,5 | 5,0 |

| Unit Weight (kg/m) | ||||||||||||

| Ø42,2 | 1 1/4 | 1,98 | 2,45 | 2,54 | 2,81 | 2,90 | 3,08 | 3,34 | 3,43 | 3,77 | 4,18 | 4,59 |

| Ø42,4 | 1 1/4 | 1,99 | 2,46 | 2,55 | 2,82 | 2,91 | 3,09 | 3,36 | 3,44 | 3,79 | 4,21 | 4,61 |

| Ø48,3 | 1 1/2 | 2,28 | 2,82 | 2,93 | 3,25 | 3,35 | 3,56 | 3,87 | 3,97 | 4,37 | 4,86 | 5,34 |

| Ø60,3 | 2 | 2,88 | 3,56 | 3,70 | 4,10 | 4,24 | 4,51 | 4,90 | 5,03 | 5,55 | 6,19 | 6,82 |

| Ø63,0 |

| 3,01 | 3,73 | 3,87 | 4,30 | 4,44 | 4,72 | 5,14 | 5,27 | 5,82 | 6,49 | 7,15 |

| Ø73,0 | 2 7/8 | 3,50 | 4,35 | 4,51 | 5,01 | 5,18 | 5,51 | 6,00 | 6,16 | 6,81 | 7,60 | 8,38 |

| Ø76,1 | 2 1/2 | 3,65 | 4,54 | 4,71 | 5,23 | 5,41 | 5,75 | 6,27 | 6,44 | 7,11 | 7,95 | 8,77 |

| Ø88,9 | 3 | 4,29 | 5,33 | 5,53 | 6,15 | 6,35 | 6,76 | 7,37 | 7,57 | 8,37 | 9,37 | 10,34 |

| Ø101,6 | 3 1/2 | - | - | - | 7,06 | 7,29 | 7,76 | 8,47 | 8,70 | 9,63 | 10,78 | 11,91 |

| Ø114,3 | 4 | - | - | - | 7,97 | 8,23 | 8,77 | 9,56 | 9,83 | 10,88 | 12,18 | 13,48 |

| Ø127,0 |

| - | - | - | 8,87 | 9,17 | 9,77 | 10,66 | 10,95 | 12,13 | 13,59 | 15,04 |

| Ø139,7 | 5 | - | - | - | 9,78 | 10,11 | 10,77 | 11,76 | 12,08 | 13,39 | 15,00 | 16,61 |

| Ø152,4 |

| - | - | - | 10,69 | 11,05 | 11,77 | 12,85 | 13,21 | 14,64 | 16,41 | 18,17 |

| Ø159,0 |

| - | - | - | 11,16 | 11,54 | 12,29 | 13,42 | 13,80 | 15,29 | 17,14 | 18,99 |

| Ø165,1 | 6 | - | - | - | 11,60 | 11,99 | 12,78 | 13,95 | 14,34 | 15,89 | 17,82 | 19,74 |

| Ø168,3 | 6 | - | - | - | 11,83 | 12,23 | 13,03 | 14,22 | 14,62 | 16,21 | 18,18 | 20,13 |

| Ø177,8 | 7 | - | - | - | 12,51 | 12,93 | 13,78 | 15,04 | 15,46 | 17,14 | 19,23 | 21,31 |

| Ø193,7 | 7 5/8 | - | - | - | - | - | - | 16,42 | 16,88 | 18,71 | 21,00 | 23,27 |

| Ø219,1 | 8 | - | - | - | - | - | - | 18,61 | 19,13 | 21,22 | 23,81 | 26,40 |

| Ø244,5 | 9 | - | - | - | - | - | - | - | - | 23,72 | 26,63 | 29,53 |

| Ø273,0 | 10 | - | - | - | - | - | - | - | - | 26,53 | 29,80 | 33,04 |

| Ø323,9 | 12 | - | - | - | - | - | - | - | - | - | - | 39,32 |

| Ø339,7 | 13 3/8 | - | - | - | - | - | - | - | - | - | - | 41,27 |

| Outside Diameter | Wall Thickness (mm) | |||||||||||

| mm | inch | 5,5 | 6,0 | 6,5 | 7,0 | 8,0 | 9,0 | 10,0 | 11,0 | 12,0 | 13,0 |

|

| Unit Weight (kg/m) | ||||||||||||

| Ø42,2 | 1 1/4 | - | - | - | - | - | - | - | - | - | - |

|

| Ø42,4 | 1 1/4 | - | - | - | - | - | - | - | - | - | - |

|

| Ø48,3 | 1 1/2 | - | - | - | - | - | - | - | - | - | - |

|

| Ø60,3 | 2 | 7,43 | 8,03 | 8,62 | 9,20 | - | - | - | - | - | - |

|

| Ø63,0 |

| 7,80 | 8,43 | 9,06 | 9,67 | - | - | - | - | - | - |

|

| Ø73,0 | 2 7/8 | 9,16 | 9,91 | 10,66 | 11,39 | 12,82 | - | - | - | - | - |

|

| Ø76,1 | 2 1/2 | 9,58 | 10,37 | 11,16 | 11,93 | 13,43 | - | - | - | - | - |

|

| Ø88,9 | 3 | 11,31 | 12,27 | 13,21 | 14,14 | 15,96 | - | - | - | - | - |

|

| Ø101,6 | 3 1/2 | 13,03 | 14,14 | 15,24 | 16,33 | 18,47 | 20,55 | - | - | - | - |

|

| Ø114,3 | 4 | 14,76 | 16,02 | 17,28 | 18,52 | 20,97 | 23,37 | 25,72 | - | - | - |

|

| Ø127,0 |

| 16,48 | 17,90 | 19,31 | 20,71 | 23,48 | 26,19 | 28,85 | - | - | - |

|

| Ø139,7 | 5 | 18,20 | 19,78 | 21,35 | 22,91 | 25,98 | 29,01 | 31,98 | - | - | - |

|

| Ø152,4 |

| 19,92 | 21,66 | 23,39 | 25,10 | 28,49 | 31,83 | 35,12 | - | - | - |

|

| Ø159,0 |

| 20,82 | 22,64 | 24,44 | 26,24 | 29,79 | 33,29 | 36,74 | - | - | - |

|

| Ø165,1 | 6 | 21,65 | 23,54 | 25,42 | 27,29 | 30,99 | 34,64 | 38,25 | - | - | - |

|

| Ø168,3 | 6 | 22,08 | 24,01 | 25,93 | 27,84 | 31,62 | 35,36 | 39,04 | 42,67 | 46,25 | 49,79 |

|

| Ø177,8 | 7 | 23,37 | 25,42 | 27,46 | 29,48 | 33,50 | 37,46 | 41,38 | 45,25 | 49,06 | 52,83 |

|

| Ø193,7 | 7 5/8 | 25,53 | 27,77 | 30,01 | 32,23 | 36,63 | 40,99 | 45,30 | 49,56 | 53,77 | 57,93 |

|

| Ø219,1 | 8 | 28,97 | 31,53 | 34,08 | 36,61 | 41,65 | 46,63 | 51,56 | 56,45 | 61,29 | 66,07 |

|

| Ø244,5 | 9 | 32,42 | 35,29 | 38,15 | 41,00 | 46,66 | 52,27 | 57,83 | 63,34 | 68,80 | 74,21 |

|

| Ø273,0 | 10 | 36,28 | 39,51 | 42,72 | 45,92 | 52,28 | 58,59 | 64,86 | 71,07 | 77,24 | 83,35 |

|

| Ø323,9 | 12 | 43,18 | 47,04 | 50,88 | 54,70 | 62,32 | 69,89 | 77,41 | 84,88 | 92,30 | 99,67 |

|

| Ø339,7 | 13 3/8 | 45,33 | 49,37 | 53,41 | 57,43 | 65,44 | 73,40 | 81,30 | 89,16 | 96,97 | 104,73 |

|

| Lengths | ||||||||||||

|

| 5,0-7,5m | |||||||||||

|

| 5,0-8,5m | |||||||||||