HOT ROLLED PICKLED & OILED STEEL SHEETS

Hot rolled pickled and oiled steel is steel that has been descaled of an oxide film and oiled to help corrosion fight. During the pickling process, hot rolled steel is descaled in a hydrochloric acid bath. The scale-free surface benefits forming, bending, stamping, and painting both in production savings and the quality of the finished part. The pickling and oiling process produces hot rolled steel that is durable and has improved formability while providing a cleaner surface for painting with a limited barrier to rust formation.

There are a number of advantages to a pickled steel product. First, the pickling and oiling process produces a hot rolled steel that offers improved workability, including forming, bending, and stamping. HRPO steel is better for bending and deep drawing applications. Additional benefits include:

BETTER PAINTING: Hot rolled pickled and oiled products lend to easier painting due to the surface being free from impurities such as stains and rust. This allows to achieve glossy finishes with less paint and better paint adhesion that avoids chipping.

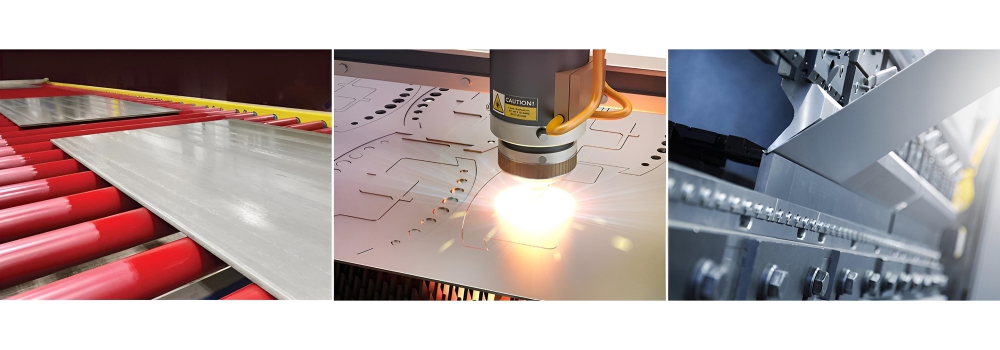

IMPROVES BENDING, FORMING and STAMPING: HRPO steel products have improved workability and, thus, improved bending, forming, and stamping. Improves lifespan of press brake and stamping dies. Achieve deeper draw with a lubricated, clean surface. Avoid delays due to consistent die cleanup.

IMPROVES WELDING: Because HRPO steel has a scale-free surface, welding is significantly improved as it eliminates weld seam grinding, achieves precise measurement and welding of large fabrications without re-work with the use of robotic welding techniques, reduces labor for manual welds. HRPO products require no pre-cleaning due to the thick oil layer of electrostatically applied microns burning off in welding.

Hot rolled pickled & oiled plate, sheet, and coil are versatile materials that are well-suited for a wide range of applications across multiple industries. Here are a few examples of applications that utilize HRPO plate, sheet, and coil:

AG wheels, Agriculture equipment, Air compressor housings, Automotive & other stampings, Cement mixers, Construction, Cranes, Filters, Forklifts, Gas cylinders, Guard rails, Heavy construction equipment, Industrial storage racks, Lawn and garden equipment, Light poles, Man lifts, Package strapping, Pipe, Propane tanks, Rack Systems, Reinforcements, Solar tracking supports, Tanks, Truck rails & trailers, Tubing, Welding finishes.

Supply Programme

Thickness 1,60 - 4,00mm

Width 700 - 1.300mm

Standards EN 10111:2008, EN 10025-2:2004, EN10149-2:2013, EN 10338:2015

Types Mill Edge PHRM, Trimmed PHR

|

| Cold Forming Steels | Structural Steels | Cold Forming Steels | Cold Forming Steels |

| Drawing and Deep Drawing Steels | Medium and High Strength General Structural Steels | Medium and High Strength Low Alloyed Steels | High Yield Strength Dual- Phase Steels | |

| DD11 | S235JR | S315MC | HDT580X | |

| DD12 | S275JR | S355MC |

| |

| DD13 | S355JR | S420MC |

| |

| DD14 |

|

|

| |

| Thickness | Min. Width | Max. Width | ||

| 1,60 - 4,00 | 700 | 1300 | ||